Why You Need To Start Using Compressed Air Systems

Two of the highest public concerns are cleanliness and efficiency. If you doubt this, all you have to do is open up a newspaper. You’ll find scores of reviews, reports, and even lawsuits directly related to one or both of these concerns. For these reasons, cleanliness and efficiency are the top concerns for businesses as well. Often, if you’re in a mass production business, you’ll be under close scrutiny to ensure that you are following proper codes and meeting these expectations. With so many strict health codes and environmental codes, it can be difficult to make sure you’re up to par. However, there are many resources you can use to help keep your business out of trouble. One of the best ways to do this is to use compressed air.

Why Compressed Air?

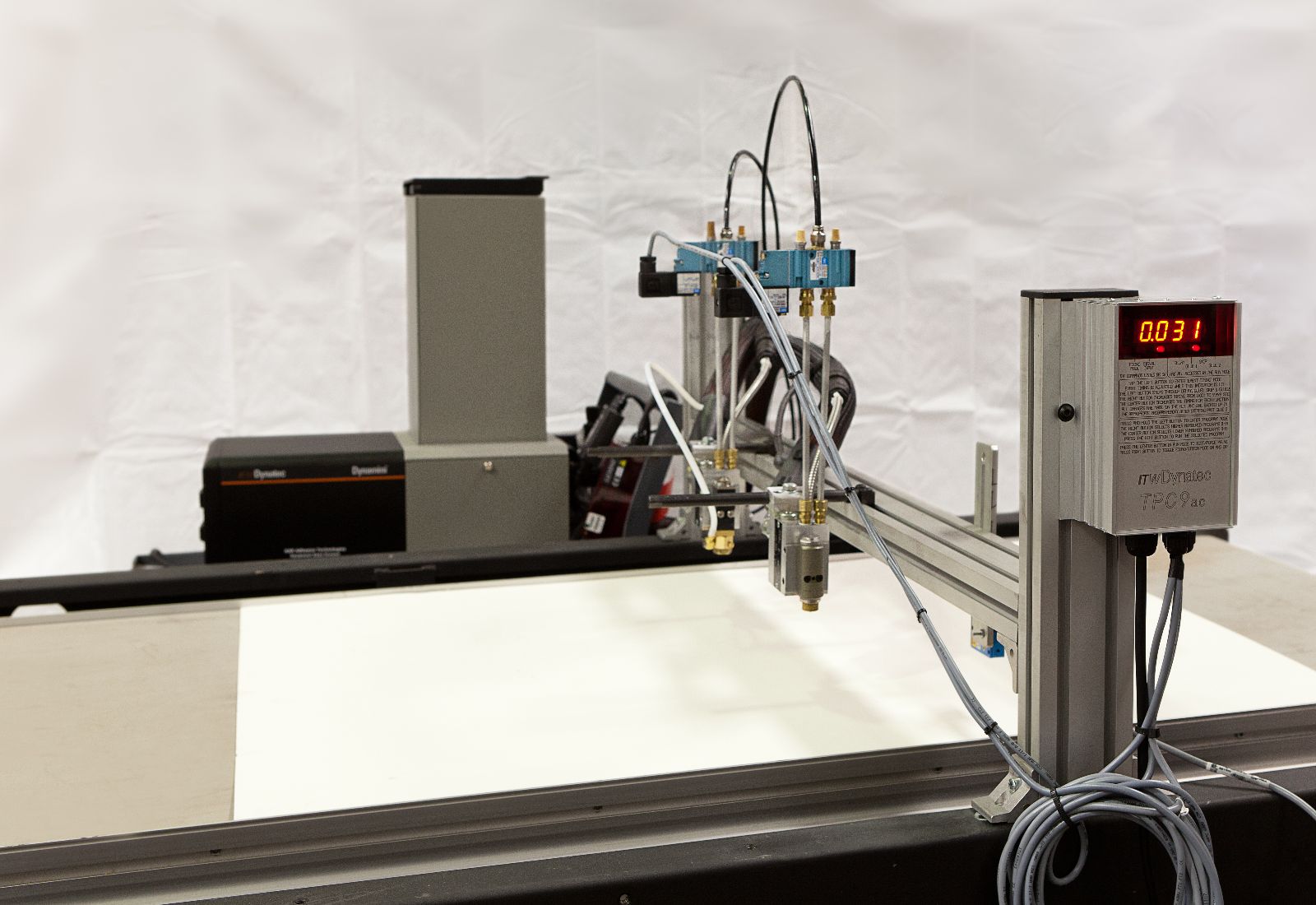

Compressed air can be used for a variety of purposes and is commonly found in many mass production businesses. Regardless of what your business is, you’ll be able to find wonderful uses and applications for compressed air in your area of expertise. If your profit margins aren’t what they should be, or you’re looking to add more efficient methods to your production, look into hiring compressed air system installers.

What Is Compressed Air Used for?

Compressed air can be used for a variety of different things, like cleaning, sorting product, and packaging. You can install specific stations for using air, or have a company come in and install an extensive system.

Glass Production

If your glass company isn’t producing the expected profits, you might want to look into your air systems. Have someone come out and analyse the air expenditures. You may have a faulty system. Repairing this error can have an immense impact on your profit margins. You may be able to turn your quarter around and make some great progress in the future.

Pharmaceuticals

You need certifiably purified air to make sure all the tablets and pills you produce are clean and free of dust. Hiring the right company to provide compressed air will make a big difference. With the right system, you can handle all the cleaning, sorting, and packaging while mainlining high purity levels for your product and minimising, if not eliminating, contamination in your production site.

Plastics

With growing technology, the options you have for choosing the perfect compressed air system for your plastic manufacturing and production site are expanding quickly. There are now more involved processes to help you with your melding, including four-stage centrifugal processes and four-stage reciprocating technology. With so many options to keep your production lines flowing steadily and your business in high demand, you’ll be sure to make great choices that will help with the future of your company.

If you’re in the business of manufacturing and mass production, you need to look into a reputable compressed air company. It will help you make changes that will have a great effect on the future of your company.

How Your Business Can Benefit From Protective Screens

What Are The Main Advantages Of Using A Marketing Agency?

7 Benefits Of Using Internet Marketing For Your Business

A Guide To Advertising A Brand New Business